|

|||||

| Home | Research | For Teachers | HISTORY Level 1 Level 2 Level 3 |

PRINCIPLES Level 1 Level 2 Level 3 |

CAREER Level 1 Level 2 Level 3 |

| Gallery | Hot Links | What's New! | |||

| Web Administration and Tools | |||||

|

|||||

| Home | Research | For Teachers | HISTORY Level 1 Level 2 Level 3 |

PRINCIPLES Level 1 Level 2 Level 3 |

CAREER Level 1 Level 2 Level 3 |

| Gallery | Hot Links | What's New! | |||

| Web Administration and Tools | |||||

![]()

The industry team of Lockheed Martin and Boeing is working with the U.S. Air Force and Pratt & Whitney to develop the F-22 to replace the current F-15 beginning in 2004. First flight was September 7,1997

Lockheed Martin Aeronautical Systems

The F-22 Raptor is an air dominance fighter with much higher capability than current U.S. Air Force aircraft. Compared with the F-15 it is designed to replace, the aircraft has higher speed and longer range, greater agility, enhanced offensive and defensive avionics, and reduced observability. Furthermore, both the air vehicle and the engine designs emphasize reliability and maintainability of systems, and are the result of a team approach called Integrated Product Development.

The F-22 can carry medium and short-range air-to-air missiles in internal bays, and has an in internal 20-mm cannon and provisions for carrying precision ground attack weapons. Pilots will have a "first-look, first-shot, first-kill" capability because of the Raptor's stealth properties and advanced sensors. In addition, the avionics suite is a highly integrated system that will allow the pilot to concentrate on the mission, rather than on managing the sensors as in current fighters.

Much of the increased capability is based on the materials in the engine, the structure, and the skin. Efficient processing methods also contribute to higher reliability, lower costs, and simplified maintenance. This article describes some of those materials and processes.

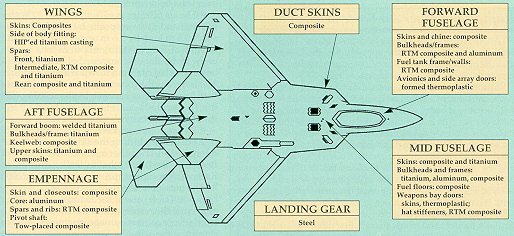

Traditional aircraft materials such as aluminum and steel make up about 20% of the F-22 structure by weight. Its high-performance capabilities require significant amounts of titanium (42% of all structural materials by weight) and composite materials (24% by weight). These are stronger and lighter than traditional materials, and offer better protection against corrosion. Titanium also offers tolerance to higher temperatures. In fact, titanium accounts for a larger percentage of the structural weight on the F-22 than any other current U.S. fighter.

| Raptor and other Air Force birds of prey |

| The official nickname for the

Lockheed Martin-Boeing F-22A is Raptor. It was chosen and approved by the U.S. Air Force,

and the nickname was officially announced at the F-22 rollout ceremony in Marietta,

Georgia, on April 9, 1997. Raptors are very strong, usually large birds, with hooked beaks and sharp talons. The name Raptor was chosen for the F-22 because it incorporates the strongest characteristics of all birds of prey. The F-22 emulates the silent flight of the owl with its stealth; it carries out swift attacks like a hawk with its speed; it expends as little energy as it has to in flight, much like the condor that "coasts" on air currents; it has the speed of a hawk, and the agility of a falcon. The F-22 also has the lethality of the harpy eagle, which weighs up to 20 pounds, has a wingspan of eight feet, and is white, gray and black in a camouflaged pattern. It has talons bigger than a grizzly bear's claw. The F-22 continues a tradition of U.S. Air Force aircraft, particularly fighters and attack aircraft, that dates back to the Curtiss Hawks of the 1920s, and continues to the current F-15 Eagle and F-16 Fighting Falcon. |

On the F-22, the number of parts made from thermoset composites is approximately a 50 / 50 split between epoxy resin parts and bismaleimide (BMI) parts. Exterior skins are all BMI, which offers high strength and high-temperature resistance.

Thermoplastic composites are also highly durable materials but, unlike thermosets, thermoplastics can be reheated and re-formed. However, thermo-plastics proved to be more expensive and more difficult to incorporate in the F-22 than had been hoped in the early days of the program. As a result, although thermoset composites comprise about 24% of airframe structural materials, thermoplastics are only about 1%. They -ire being applied on the F-22 for items such as doors for the landing gear and weapons bay, where tolerance to impact damage is required from things such as small rocks that may be kicked up from the runway.

The F-22 is the first aircraft to take advantage of resin transfer molding (RTM) of composite parts. RTM is a method of composite parts fabrication well suited to economically fabricating complex-shaped details repeatedly to tight dimensional tolerances.

Large composite parts traditionally are formed by applying and pressurizing hundreds of layers of fabric that contain a pre-embedded resin, and curing them in an autoclave. This is a very time-consuming and labor-intensive process.

In the RTM process, fibrous preforms are first shaped under vacuum from stacks of fabric, and then placed in metal tooling that matches the shape of the part. The tool is then injected with heated resin under pressure. The benefit of matching the metal tooling to RTM is a high level of part reproducibility, consistency in assembly operations, and economies of scale.

RTM is used to fabricate more than 400 parts of the F-22 structure, ranging from inlet lip edges to load-bearing sine-wave spars in the fighter wings. At Boeing, RTM has reduced the cost of wing spars by 20%, and has cut in half the number of reinforcement parts needed for in stalling the spars in the wings. Both bismaleimide and epoxy parts are fabricated by RTM.

The composite pivot shaft is an application of automated fiber placement (AFP) technology, which was combined with unique tooling approaches to produce a lightweight composite structure that replaced titanium in a flight-critical application - the F-22 horizontal stabilizers.

AFP technology makes possible the exact fiber positioning required to achieve the complex geometry of the pivot shaft. It has a 25-cm (10in.) diameter cylinder at one end, a rectangular spar about 10 cm (4 in.) wide at the other, and an offset in the transition area. Its shape can be likened to that of an oversized hockey stick.

It is composed of more than 400 plies of composite tow tapes ranging from 3 to 12 mm (1 / 8 to 1 / 2 in.) wide. The shaft is cured in stages to prevent internal cracking and eliminate wrinkles, as no allowance is made for voids in the shaft. After layup, the shafts are nondestructively inspected and tested.

Production requires up to 60 days, but weight is reduced by 40 kg (90 lb) per shipset (two shafts) over titanium, which is an extremely large amount of weight to take out of an aircraft at one time. Thicker tow tapes are planned for future pivot shafts, which should greatly reduce production time.

Hot isostatic pressing (HIP) is a process in which metallic castings are subjected to very high temperatures in a static pressure environment of >70 MPa (10 ksi). On the F-22, structural titanium castings are HIP'ed to collapse internal shrinkage cavities and diffusion-bond the walls of the cavities. Six large structures on the F-22 are HIP'ed: the rudder actuator housing (one for each rudder); the canopy deck; the wing side-of-body forward and aft fittings (four total, two for each wing); the aileron strongback (one for each aileron, two total); and the inlet canted frame (one each for the left and right inlets). The canted frame was originally a four-piece assembly. By switching to a casting, mechanical joints were eliminated and machining was minimized.

Electron beam (EB) welding is helping Boeing and Aerojet, its supplier, build lighter-weight titanium assemblies for the aft fuselage. Parts are EB Welded in a vacuum chamber to prevent exposure to oxygen, which can create a deleterious brittle surface. Compared with other methods, electron beam welding enables much more reliable joints when welding titanium parts more than an inch thick.

The process also reduces the need for fasteners in some fuselage components by up to 75%, which decreases weight, simplifies the assembly process, and avoids the costs associated with fasteners. The reduction in the number of fasteners also means fewer openings for possible fuel leaks.

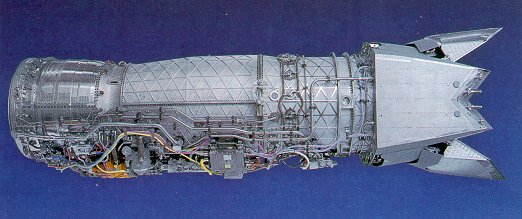

The product of more than 40 years of research into high-speed propulsion systems, the Pratt & Whitney F119 is proof that high-technology does not have to be complicated. A balanced approach to the design process led to an engine as innovative in its reliability and support as in its performance. Assemblers and flight line mechanics participated in the F119's design from its inception. The result is that ease of assembly, maintenance, and repair are designed into the engine. For example, the F119 cuts requirements for support equipment and labor by half, which also saves precious space in airlifters during combat zone deployments. The engine will require 75% fewer ship visits for routine maintenance than its predecessors.

The F119 has 40% fewer major parts than current fighter engines, and each part is more durable and does its job more efficiently. Computational fluid dynamics-airflow analyzed through advanced computers-led to the design of engine turbomachinery of unprecedented efficiency, giving the F119 more thrust with fewer turbine stages.

In fact, the F119-PW-100 engine develops more than twice the thrust of current engines under supersonic conditions, and more thrust without afterburner than conventional engines with afterburner. Each F-22 will be powered by two of these 35,000-pound-thrust-class engines. By comparison, the engines powering the Air Force F-15 and F-16 fighters have thrust ratings ranging from 23,000 to 29,000 pounds.

Jet engines deliver additional thrust by directly injecting fuel at the engine exhaust. The process, called afterburner, gives the aircraft a rocket-like boost as the fuel ignites in the exhaust chamber. The tradeoff is higher fuel consumption, a greater amount of heat, and consequently, greater visibility to the enemy. However, the F119 engine can push the F-22 to supersonic speeds above Mach 1.4 even without firing the afterburner, which gives the fighter a greater operating range and allows for stealthier flight operation.

The Fll9 engine nozzle for the F-22 is the world's first full production vectoring nozzle, fully integrated into the aircraft/ engine combination as original equipment. The two-dimensional nozzle vectors thrust 20 degrees up and down for improved aircraft agility. This vectoring increases the roll rate of the aircraft by 50%, and has features that contribute to the aircraft stealth requirements.

Heat-resistant components give the nozzles the durability needed to vector thrust, even in afterburner conditions. With precision digital controls, the nozzles work like another aircraft flight control surface. Thrust vectoring is an integrated part of the F-22's flight control system, which allows for seamless integration of all components working in response to pilot commands.

The following information was extracted from the May 1998 issue of

the technical magazine,

ADVANCED MATERIALS & PROCESSES.

Permission was granted to ALLSTAR by the magazine to use the preceding materials.

For more information about this article, please contact Margaret W. Hunt, the magazine's editor

Send all comments to ![]() aeromaster@eng.fiu.edu

aeromaster@eng.fiu.edu

© 1995-98 ALLSTAR Network. All rights reserved worldwide.

| Funded in part by | Used with permission From ASM International |

|

Updated: February 23, 1999