Using Design, Build and Test

Projects for Improving the Design of

Fluid-Thermal Systems and

HVAC Design

Abstract

The

goals of the newly-awarded project by NSF are to adapt and implement proven

concepts from previous NSF projects in order to integrate hands-on experiments

in traditional thermal science lecture courses and to reorient traditional

teaching laboratory courses with design, build, and test (DBT) activities. In particular, the following principles and

methods are adapted: a hands-on experience integrated

to abstract concepts discussed in lectures, a clear linkage to industrial

applications, and Design Build and Test (DBT) projects. Specifically, two DBT course modules are

developed: the heat exchanger and scaled building air-conditioning system. The

project reforms the current thermal science stem curriculum with changes to

three required lecture courses in such a way that the contents of the

stand-alone ME lab course is integrated with the lectures through the execution

of DBT activities. This adaptation

enhances students’ learning of thermal science subjects by providing students

an enhanced, open-ended design problem experience in the mid-stage of the

curriculum rather than near the end when the senior design project is

required. It supports improved

comprehension of the thermal-fluid contents through practical application and

immediate, relevant implementation, rather than a fragmented learning

process. DBT activities enhance

students’ critical thinking skills with the decision-making and close-loop

accomplishment experience. Through a

planed evaluation process, the project leads to three outcomes to demonstrate

that the DBT approach better equips students with an ability to apply

mathematics, science, and engineering to thermal-fluid systems design, that the

students can have a platform to practice teamwork, professional and ethical

responsibility, and that the reformed curriculum contributes to an increase in

student’s interests in thermal/fluid subjects, better retention rate, and more

attraction to prospective students.

Finally, the developed process ensures a favorable cooperative learning

environment with a strong sense of accomplishment for the underrepresented

student population. This presentation

focuses on the progress of the project in the following areas: (1) Planned

activities, (2) student design team’s efforts, and (3) pre-project evaluation

serving as a benchmark for project implementation evaluation.

Introduction

The principal

investigators are committed to adapting and implementing proven concepts from

three previous CCLI projects, from the

The objectives of this reform are three-fold: (1) to increase student achievement in the traditional lecture course in thermal sciences and to gain better comprehension of the course content, and (2) to increase engineering design experience in the overall curriculum, and (3) to develop critical thinking skills, and promote more synectic thinking, i.e. the ability to relate seemingly disconnected topics and use them together to solve open-ended problems. Integrating hands-on experimental components into the traditional lecture course will create a more cooperative learning environment, and will provide learning opportunities for sensate learners (those the learn better by seeing and doing rather than through abstract thinking and conceptualizing). In addition, the laboratory assignments with their associated data analysis will provide an alternative to the standard end-of-the-chapter problems with their single-point solutions. Reorienting the traditional laboratory course from the execution of well defined encapsulated laboratory experiments to a DBT format will address the need for more open-ended design problem experience in the overall curriculum, and more specifically support improved comprehension of the thermal-fluid content through practical application. Furthermore, requiring that the designs be tested incorporates experimental planning and data analysis as well.

Problem and Needs

Despite

various levels of efforts, the

Within the

Mechanical and Materials Engineering (MME) Department, informal research is

showing that close to 50% of our students are sensate learners, who are

“good with their hands”, and who enjoy as well as expect hands-on experience as

part of their education. This is

probably due to the fact that almost all of our students are first or second

generation American, with a sizable minority coming from high schools outside

the

Another issue facing FIU, being located in a generally poor to lower income community (Miami has been rated the poorest city in the US, for the last two consecutive years), is that large numbers of our students work outside of school and essentially all of our students commute from all points in Dade and Broward counties. This makes it difficult for our students to collaborate effectively on design projects, particularly during the fabrication stages. Students need equipped teaching laboratories that are open and staffed so they can work on their projects during class time. Clearly, more equipped and accessible facilities are needed for student use.

Mechanical

Engineering has been particularly hard hit by economic constraints with respect

to its teaching laboratories. The cost

of commercially available teaching equipment exceeds the capital

available. With the shift to a

software-driven society, the administration, as well as government agencies,

find it hard to justify the expenditures for laboratory equipment with prices

near that of research grade equipment.

Unfortunately, the lower cost equipment ($5K to $20K) is very specific

in scope and is not well suited to open ended problems. As has been observed by various scholars and

international students, the level of hands-on training for Mechanical

Engineering students in

Design, Built, and Test

(DBT) Projects

To address the problems and needs identified in the last section, the principal investigators propose a specific plan of curriculum reform. This plan is based on the adaptation of successful curriculum enhancements performed by other NSF awardees of CCLI grants. The plan focuses on reorientation of EML 4906L Mechanical Engineering Laboratory from a traditional encapsulated experimental experience into a DBT experience for the students

DBT Laboratory Experience

The plan is based on the work done at the University of Idaho University of Idaho

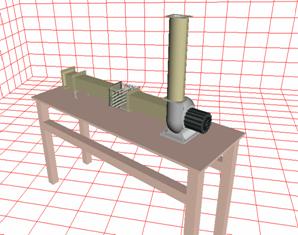

Cross Flow Heat Exchanger DBT. The PI(s) will update a current piece of teaching equipment in the laboratory (PA Hilton Cross Flow Heat Exchanger Apparatus). The device is well suited for the DBT adaptation as it has a removable test section, in which the students can place their heat exchanger (HE) sections. The apparatus is equipped with a blower system to draw room air through the HE section as various air speeds. Pressure drop can be measured as well as air speed through the section. The advantage of using room air is simplicity, however, the negative aspect of the apparatus is that it is not configured for a second fluid loop. The PI(s) intend to add a temperature controlled hot water system to the apparatus and additional instrumentation to facilitate DBT projects. The fluid loop can be accomplished through either a recirculating temperature controlled bath, or a tank-less water heater and pump assembly. Both systems are commercially available. The water will be heated to 80‑85 °C and cooled by the air drawn through the HE sections built by the students. Additional instrumentation is necessary so that the water flow rate and temperature into and out of the HE section is monitored. This can be accomplished with commercially available thermocouples and flow meters. A small assortment of instrumentation components will be needed to convert the signals from the sensors to usable output. This will be accomplished by several means, and a detailed trade study needs to be accomplished prior to final selection. While digital computer based acquisition is preferred, in many cases, these systems are not user-friendly to students, and they are not always amenable to rapid change out of projects. Manual bench systems such as dedicated digital readouts, and ten channel thermocouple units provide flexibility and adaptability as well. In any event, instrumentation needs to be “turnkey” for DBT projects, allowing for rapid change-out of student projects, sustainable operation without the need for software licenses, and with negligible learning curves. Figure 1 illustrates a schematic of the common test facility with a student-built prototype.

The

most important part of the DBT approach is to facilitate the ability of the

students to actually model and build prototype systems for the test phase. The cross-flow heat exchanger is essentially

a duct through which one fluid (e.g. cold air) flows. Across the duct are placed an array of tubes

carrying the second fluid in the system (e.g. hot water), which are oriented

perpendicular to the flow of the first fluid, i.e. the tubes are in said to be

cross-flow. The engineering problem is

maximizing the performance of the system, which is done through several

parameters, the relationship of which is not trivial, nor fully

understood. The configuration is well

suited to student projects as it only required students to configure a group of

tubes across the test section, connecting the tubes together to form a closed

fluid path. However, the permutations of

this simple configuration are numerous allowing for students to exercise

creativity as well as engineering intuition.

More advanced designs can be accomplished by adding thin fins to the

tubes creating an assembly similar to those used in air conditioning systems

and automotive radiators.

The

most important part of the DBT approach is to facilitate the ability of the

students to actually model and build prototype systems for the test phase. The cross-flow heat exchanger is essentially

a duct through which one fluid (e.g. cold air) flows. Across the duct are placed an array of tubes

carrying the second fluid in the system (e.g. hot water), which are oriented

perpendicular to the flow of the first fluid, i.e. the tubes are in said to be

cross-flow. The engineering problem is

maximizing the performance of the system, which is done through several

parameters, the relationship of which is not trivial, nor fully

understood. The configuration is well

suited to student projects as it only required students to configure a group of

tubes across the test section, connecting the tubes together to form a closed

fluid path. However, the permutations of

this simple configuration are numerous allowing for students to exercise

creativity as well as engineering intuition.

More advanced designs can be accomplished by adding thin fins to the

tubes creating an assembly similar to those used in air conditioning systems

and automotive radiators.

To facilitate student fabrication, some constraints need to be imposed: the tubing will be commercially available copper tube, the test section will be formed using transparent acrylics (e.g. Plexiglas or Lexan), and silicon tubing will be used to connect the tubes together. Alternatively, more motivated students can use available copper fittings and solder their systems together. Two part epoxies will be used for fastening and holding components together. Students will need access to basic shop tools and equipment in the teaching laboratory in close proximity to the testing apparatus. As well as to have a small inventory of raw materials. Additionally, precut pieces of materials should be made available (particularly the walls of the test section). Commercially available components are available as well (Heatcraft, Inc.) In any event, the laboratory will need to be equipped with a drill press and a band saw (table top is sufficient, home shop quality) soldering equipment and raw materials.

Student design will be facilitated by commercially available software specifically for designing heat exchangers of this configuration (one example is EVAP-COND developed by NIST). The software is designed for the industrial community so the learning curves are minimal. Students can use the software to make preliminary estimates of system performance and to rapidly do iterative design activities to improve their designs. Iterative design is a key component to developing intuitive engineering knowledge, and serves to strengthen the understanding of fundamental principles. Yet it is one of the least used learning activities in engineering education, mainly because of the pressure to cover a lot of materials superficially rather than to cover one thing in depth and to completion. The DBT activity provides the students with an opportunity to focus on a single problem from concept to reality.

After the design is finalized based on engineering analysis, a prototype is made. A team of two to three students can be formed to build and test their design. The energy balance is calculated from the test results, which include inlet and outlet temperatures and flow rate (determined from the velocity measurements) of two fluids.

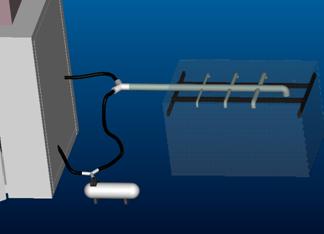

Scaled Conditioned-Air Duct System in Building DBT. The PI(s) will develop a common facility that allows students to build and test their design of a scaled air distribution duct system in a building model. The common facility consists of an air supply from a compressed air line available in the lab, and a 6x6x6 ft freezer box that cools the compressed air to the desired temperature (see Fig. 2). A mixing box (not shown) is also constructed to allow fine-tuning of supply temperature and flow rate of conditioned air. Students are required to build a scaled air distribution (duct) system to supply conditioned air to a model building. The types of building for the projects will be limited to a simple high ceiling warehouse, or one story office building with one cooling zone. An existing collaboration with FIU School of Architecture will allow for scale models to be fabricated easily. The material for both the building and ducts is Plexiglas, which permits easy flow visualization. Also, the model building can be easily assembled and dissembled.

A

team of three to five students is formed first to conduct cooling load

calculation based on the assigned R-values and a 10 oC temperature

difference between the indoor and outdoor.

The load is then scaled to fit the model building. Students make their open-ended decisions on

the layout, and sizing of the duct system, and select a supply temperature and

flow rate. After a few iterations, they

will finalize their design-and-build decision and build their system. The duct system will be installed in the

model building and connected to the supply air.

Thermocouples and velocimeters will be installed to monitor the

temperatures and flow. A dyed smoke test

can also be used to test the uniformity of air distribution. The test results include pressure drop,

temperatures, flow rate, energy usage and energy balance (cooling load

validation). Initially, the humidity will

not be monitored; however, students are encouraged to discuss the potential

effects of non-uniformity of air/wall temperature on moisture accumulation in

building materials.

A

team of three to five students is formed first to conduct cooling load

calculation based on the assigned R-values and a 10 oC temperature

difference between the indoor and outdoor.

The load is then scaled to fit the model building. Students make their open-ended decisions on

the layout, and sizing of the duct system, and select a supply temperature and

flow rate. After a few iterations, they

will finalize their design-and-build decision and build their system. The duct system will be installed in the

model building and connected to the supply air.

Thermocouples and velocimeters will be installed to monitor the

temperatures and flow. A dyed smoke test

can also be used to test the uniformity of air distribution. The test results include pressure drop,

temperatures, flow rate, energy usage and energy balance (cooling load

validation). Initially, the humidity will

not be monitored; however, students are encouraged to discuss the potential

effects of non-uniformity of air/wall temperature on moisture accumulation in

building materials.

The maintenance cost of the DBT facilities after the project finishes will be absorbed through the departmental lab management fund allocated annually.

Course Integration with DBT Experience

The two DBT lab modules will become available during the offering of the following courses in a semester:

EML 4140 Heat Transfer (3 credit hours) Students are required to register additional one credit hour for EML 4906L Mechanical Engineering Laboratory concurrently with EML 4140. The meeting hours for EML 4906 will be flexible. Students are given an orientation for DBT at the beginning of the semester, and the planning and execution of DBT experience will be synchronized with the lectures of Heat Transfer.

EML 4706 Design of Thermal and Fluid Systems (3 credit hours) DBT#2 will be an integrated part of this course. The instructor of the course will work closely with the lab technician on scheduling the lab hours so that the DBT activities will follow a similar structure to EML 4140, as shown in Table 2. Emphasis is placed on flow rate, pumping power and energy balance requirements. The thermal comfort and moisture requirements need not be addressed.

EML 4603 Air Conditioning Design (3 credit hours) DBT #2 will be an integrated part of this course. For those students who already taken EML 4706 before taking EML 4603, their project requirement will be adjusted to reflect a new challenge. Such adjustments include a different building model, or multi-zone air distribution. The basic common facility developed will be able to handle such individual project requirements with little modification. The students, on the other hand, will be able to have a variety of options to complete their DBT project. Table 3 outlines the relation between the lecture subjects and DBT experience.

Progress to Date

The NSF project is divided to two tasks that are carried out over a two-year period. The first task is to design and build the lab system. The second task is to apply the DBT modules to the curriculum.

A team of four ME senior students was assigned the task to design the entire laboratory system during the Fall semester, 2004. Figure 4 shows the schematic of the completed design. The involvement of the senior students in the NSF project from the beginning will not only enable the faculty to have direct inputs from the students on the project implementation, but also give those students a unique opportunity to design a system that serves future students design needs, a process of “designing for design”. Based on the design the materials and equipment have been or are going to be purchased to start the construction phase of the project.

The senior design process involves the following steps:

· Concept synthesis including literature review, concept generation, concept reduction;

· Detailed design including the following components design: Cold chamber, duct system testing facility, cross flow heat exchanger and DBT experiments floor layout

· Bill of materials

· Engineering analysis including both mechanical engineering analysis and failure mode analysis

Pre-project

Student Surveys

In order to evaluate the outcome of the DBT project, we conducted an initial student survey to gauge the students’ attitude towards the concept of DBT projects and effect on the ME education. The survey was conducted near the end of the Fall semester, 2004, and consisted of a total 24 questions, in which the majority of the questions are directly related to various aspects of DBT concept. Table 1 lists the survey questions. Students from four classes in the area of Thermal/Fluid areas were asked to response to the questions by selecting various answers. Questions 1 to 7 calls for specific answers. For Question 7, the following choices were given:

A. Overwhelmingly engineering science oriented.

B. Mostly engineering science oriented.

C. Balanced between engineering science and design.

D. Mostly design oriented.

E. Overwhelmingly design oriented.

For the rest of questions, students were asked to choose from different degrees of agreement:

A. Strongly agree

B. Agree

C. Neutral

D. Disagree

E. Strongly disagree.

(a)

Figure 4 Presentation of by student team design for their senior design project: (a) Entire system; (b) Cross Flow Heat Exchanger (CFHE) and (c) Duct System Testing Facility (DSTF)

Table 1 Mechanical and Materials Engineering Student Survey - Design, Analysis and Test Components

|

1 |

What

is your gender? |

|

2 |

What

is your ethic background? |

|

3 |

How

many MME Laboratory Courses have you taken? |

|

4 |

Have

you taken EML 3126 Transport Phenomena? |

|

4 |

Have

you taken EML 4140 Heat Transfer? |

|

5 |

Have

you taken EML 4706 Design of Fluid/Thermal Systems? |

|

6 |

Have

you taken any or plan to take any HVAC courses? |

|

7 |

Rate

the balance of subject matter in the MME curriculum (check the one that you

agree with the most). |

|

8 |

Fluid

Mechanics is a more complex subject than Structural Mechanics? |

|

9 |

Heat

Transfer and Thermodynamics are more complex subjects than Structural

Mechanics? |

|

10 |

Students

prefer Structural Mechanics over Heat Transfer/Thermodynamics because it is

more physical and the phenomena can be envisioned easier? |

|

11 |

As

a student, hands-on learning experiences help me learn complex material and

concepts. |

|

12 |

I

prefer learning through hands-on application more than from strictly from

textbook and lecture? |

|

13 |

The

MME curriculum does a very good job of integrating design and engineering

analysis skills? |

|

14 |

The

MME curriculum does a very good job of developing design skills, methods and

practices? |

|

15 |

I

feel that the MME curriculum is a collection of totally independent courses

with little opportunity to integrate the knowledge learned in previous

courses. |

|

16 |

Instructors

regularly test my knowledge of engineering science through practical,

real-world design problems and projects. |

|

17 |

Laboratory

courses should be integrated tightly with core lecture courses (e.g.

Transport Lab with Transport Phenomena lecture). |

|

18 |

MME

Laboratory courses are well integrated with lecture material in core courses. |

|

19 |

Laboratory

experiments and demonstrations should be integrated with the core course

lectures. |

|

20 |

My

instructors in my core lecture courses regularly use learning aids and

demonstrations to support the lecture material. |

|

21 |

I

am given the opportunity to design and test engineering systems? |

|

22 |

When

I am submit design oriented assignments, I have the

opportunity to get feedback through design review so I can make improvements. |

|

23 |

When

I submit design oriented projects, I am given the opportunity to evaluate the

design through simulation and/or prototyping testing. |

|

24 |

Open-ended

design projects allow me to be more creative in my solutions. |

|

25 |

Open-ended

design projects force me to investigate and explore engineering science

material in an independent manner. |

|

26 |

I

get more motivated to learn and practice my engineering skills through

project work as opposed to formal examinations. |

|

27 |

The

MME curriculum does a good job of integrating the material in two or three

core courses when I do major projects. |

|

28 |

I

enjoy team projects and feel they are effective for developing my engineering

skills. |

|

29 |

Team

projects allow lazy and poor students to get the same grade without doing the

same level of achievement. |

|

30 |

I

don’t like to work on team projects, because it is inconvenient (i.e. impacts

my schedule). |

|

31 |

I

don’t like to work on team projects, because there are always students who do

less work than me and this leads to confrontation. |

|

32 |

Cheating

is a big problem in the MME department. |

|

33 |

I

have first hand knowledge of people who have cheated on exams, homework,

and/or projects. |

|

34 |

With

increased use of computer assignments, it will be easier for students to

cheat on assignments. |

|

35 |

Cheating

bothers me because students are getting the same grades as me without doing

the work. |

|

36 |

When

cheating occurs in non-team assignments, the students who cheat don’t appear

to gaining much (i.e. in general, they still get poor grades) |

Questions 1 to 31 are directly related to the scope of the NSF project, while Questions 32 to 36 were designed to test the students’ attitude towards the ethical issues related to the project orientated learning.

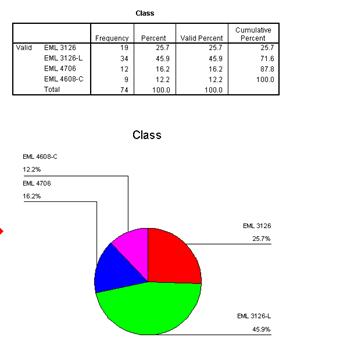

The survey was given to students enrolled in the following four classes offered by the department; EML 3126 (Transport Phenomena), EML 3126-L (Transport Phenomena Lab), EML 4706 (Design of Thermal Fluid Systems), and EML 4608-C (Mechanical Systems in Environmental Control). It is intended to be part of a pre-project evaluation and to serve as a benchmark for project implementation evaluation.

The results were analyzed in three groups. The first group was on the overall results obtained after organizing the 74 completed surveys from all four courses. The second one took the results obtained from EML 3126, which was mostly made up of students in their freshman or sophomore year of the program, and compares them to the results from EML 4706, which was made up of students in their junior and senior year. The final group simply reported the results of the final two courses EML 3126-L and EML 4608-C individually. For this paper, only the results selected from the first group are presented for the sake of briefness.

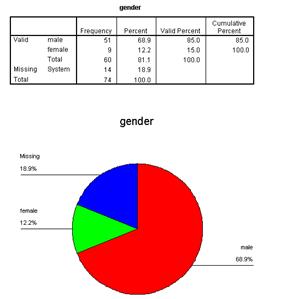

Figure 5 shows a breakdown of the number of students who completed the survey from each course and their composition. It can be seen that the majority of the sample was made up of students from EML 3126-L, followed by EML3126, then EML 4706, and finally EML 4608-C. The majority of the students surveyed were male, and the majority of the students where of Hispanic origin, which was followed in descending order by White and Other, African American and finally Asian.

When asked how many Mechanical and Materials related Lab courses the students have taken the majority of them (52.7%) seem to have taken at least three Labs. 87.8% of the students surveyed have taken EML 3126. The majority of the students surveyed have not taken EML 4140 (Heat Transfer, 73 %), EML 4706 (Design of Thermal Fluid Systems, 71.6%), nor have they taken any HVAC courses (54 %), although a significant 43.2% has taken one of the HVAC related courses.

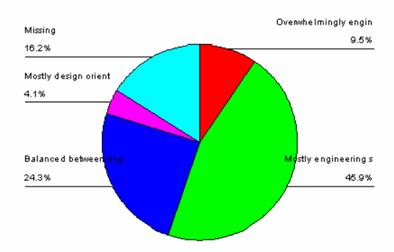

When asked to rate the balance of the subject matter offered in the Mechanical and Materials Engineering curriculum (Question 7) the majority of the students surveyed feel that the subject matter is mostly science and engineering oriented. Only 24.3% felt that it was balanced between the engineering science and design. Figure 6 shows the breakdown of their responses.

Question 8 asked if the students fell that Fluid Mechanics is a more complex subject than Structural Mechanics the majority of the students surveyed agreed that it was with 66.3% agreed or strongly agreed and 29.7% neutral. Only 2.7% disagreed. On the other hand, when asked if Heat Transfer and Thermodynamics was a more complex subject than Structural Mechanics (Questions 9) the significant percentage (40.5%) of the students surveyed felt neutral, and only 46% agreed or strongly agreed.

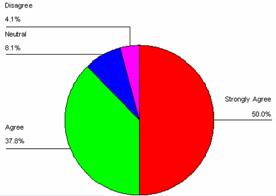

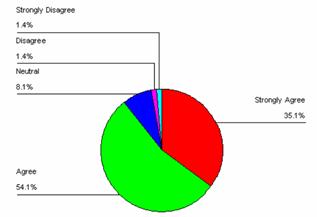

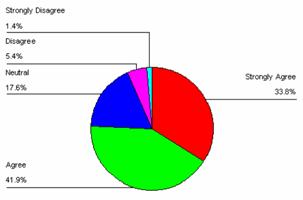

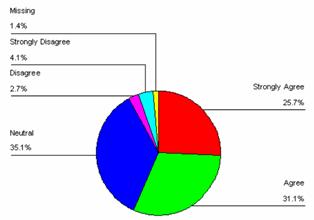

The most important questions related to the DBT concepts are Questions 11 to 31. We select a few significant findings to demonstrate that the DBT concepts are in line of students’ needs. The majority of the students surveyed strongly believe that hands-on learning experiences help them learn complex material concepts, and strongly prefer learning through hands-on application rather than strictly through textbooks and lectures. The response breakdowns for Questions 11 to 12 are shown in Figure 7.

(c)

Figure 5 Survey class composition

Figure 6 Response to Question 7

(a) Question 11 (b) Question 12

Figure 7 Responses to Questions 11 and 12

In Question 15 students were asked if they felt that the MME curriculum is a collection of totally independent courses with little opportunity to integrate the knowledge learned in previous courses. The survey showed that this statement is generally true considering 44.6% agree or strongly agreed and 34.8% disagreed or strongly disagreed. A good size of 20.5% felt neutral.

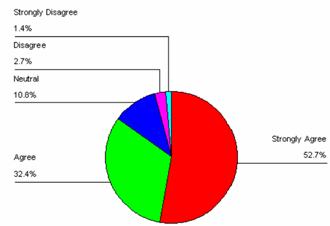

Most of the students surveyed either agree or strongly agree that laboratory courses (Figure 8a) or laboratory experiments and demonstrations (Figure 8b) should be integrated tightly with core lecture courses.

(a) Question 17 (b) Question 19

Figure 8 Response to that (a) laboratory courses should be integrated tightly with core lecture courses (e.g. Transport Lab with Transport Phenomena lecture) –Question 17, and (b) Laboratory experiments and demonstrations should be integrated with the core course lectures– Question 19.

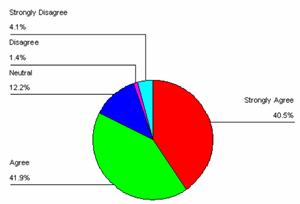

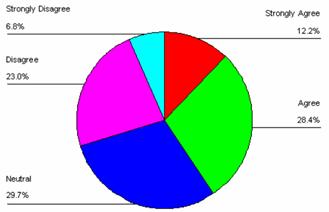

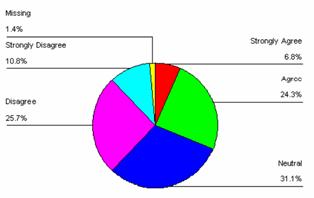

Most of the students surveyed agreed when asked if they were given the opportunity to design and test engineering systems (Question 21). The majority of the students surveyed also agree that they have the opportunity to get feedback through design reviews after they submit design oriented assignments so that they can make improvements (Question 22). However, the percentage of the students feeling neutral increases when asked if they are given the opportunity to evaluate their designs through simulation and/or prototype testing, as shown in Figure 9. This may also result from the disparity of the junior-level and senior-level students and is an indication that the junior students, although taking some lab courses, did not have a close-loop experience for project improvement.

Figure 9 Response to Question 23: When I submit design oriented projects, I am given the opportunity to evaluate the design through simulation and/or prototyping testing.

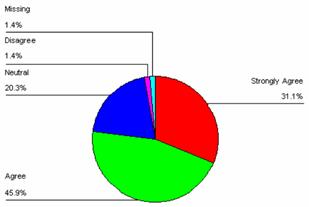

The majority of the students surveyed agree that open-ended design projects allow them to be more creative in their solutions. They also agree that open-ended projects force them to investigate and explore engineering science material in an independent manner. Figure 10 shows the response results.

(a) Question 24 (b) Question 25

Figure 10 Responses to Questions 24 and 25

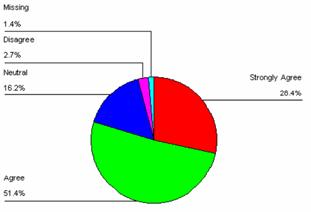

When asked if they get more motivated to learn and practice engineering skills through project work as opposed to formal examinations most students surveyed agree (Figure 11a-Question 26). The majority of the students surveyed either felt neutral or agreed that they enjoy team projects and feel they are effective for developing engineering skills (Figure 11b- Question 28).

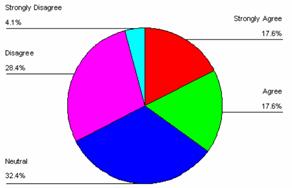

The students were divided with a significant percentage of neutral when asked if they disliked team projects because they were inconvenient (Question 30). Similar trend holds when asked if they dislike team projects because there are always students who do less work than them and this leads to confrontation (Question 31. See Figure 12). This again reflects the division in opinions between the junior class, which has less experience in team projects, and senior class, which has more complete training in project-orientated learning.

(a) Question 26 (b) Question 28

Figure 11 Responses to Questions 26 and 28

(a) Question 30 (b) Question 31

Figure 12 Responses to Questions 30 and 31

Summary

References

[1] Aung, W, and Farana, R.,

“Recent Development in International Cooperation in Engineering Education and

Research,” Invited Paper, International Seminar, Engineering Education in the

Global World, Donetsk State University, Ukraine, 2001.

(http://www.ineer.org/INEERNews/ DonSTUAung.htm).

[2] Elger, D., Budwig, R.

S. and B. Steven, “Using Design, Build,

and Test Projects in a Wind Tunnel to Improve Engineering Education,” NSF-DUI

Grant No. 9952308, 2002.

[3] Kortum, R., Dailey, M.,

Harris, C., “Formative and Summative Assessment of the IGERT Program in

Optical Molecular Bio-Engineering at UT Austin,” ASEE J. Engineering

Education, Vol. 92, No. 4, 2003